Penerapan Nomor Input dan Output PLC :

1. Jumlah Input PLC adalah 7 Input :

--- 1 Unit Input untuk Limit Feeder Reverse

--- 1 Unit Input untuk Limit Feeder Forward

--- 1 Unit Input untuk Limit Lifter Lower

--- 1 Unit Input untuk Limit Lifter Middle

--- 1 Unit Input untuk Limit Lifter Upper

--- 1 Unit Input untuk Switch Start. It's Functions to Start Process

--- 1 Unit Input untuk Push Button RESET. berfungsi untuk ORIGIN Proses

--- Total jumlah Input PLC adalah Minimum 7 Input Unit

2. Jumlah Output PLC adalah 4 Output :

--- 1 Unit Output untuk Electrical Solenoid. berfungsi untuk Moves Feeder Forward

--- 1 Unit Output untuk Electrical Solenoid. berfungsi untuk Moves Feeder Reverse

--- 1 Unit Output untuk Electrical Solenoid Type Center Closed. berfungsi untuk Moves Lifter DOWN

--- 1 Unit Output untuk Electrical Solenoid Type Center Closed. berfungsi untuk Moves Lifter UP

--- Total jumlah Outputs PLC adalah Minimum 4 Output Unit

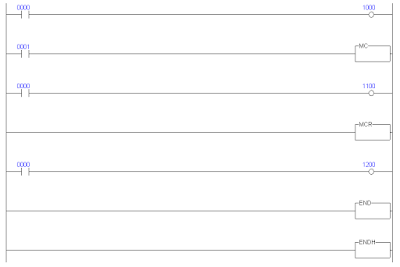

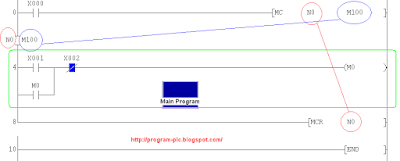

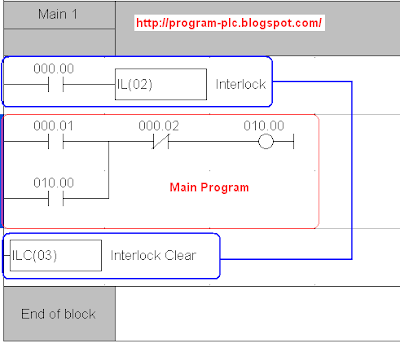

Rangkaian pemograman PLC untuk Packing Machine :

Step 1 : ( Feeder Forward to 1 )

If Feeder REV Limit = ON And Lifter UP Limit = ON And Switch Start = ON Then Cylindrical Feeder Forward = ON.

Step 2 :

1. If Cylindrical Feeder Forward = ON And Feeder FWD Limit = ON Then Cylindrical Feeder Reverse = ON.

2.a. If Cylindrical Feeder Forward = ON And Feeder FWD Limit = ON Then Cylindrical Lifter DOWN = ON.

2.b. If Lifter MID Limit = ON Then Cylindrical Lifter DOWN = OFF.

Step 3 : ( Feeder Forward to 2 )

If Feeder REV Limit = ON And Lifter MID Limit = ON Then Cylindrical Feeder Forward = ON.

Step 4 :

1. If Cylindrical Feeder Forward = ON And Feeder FWD Limit = ON Then Cylindrical Feeder Reverse = ON.

2.a. If Cylindrical Feeder Forward = ON And Feeder FWD Limit = ON Then Cylindrical Lifter DOWN = ON.

2.b. If Lifter LOW Limit = ON Then Cylindrical Lifter DOWN = OFF.

Step 5 : ( Feeder Forward to 3 )

If Feeder REV Limit = ON And Lifter MID Limit = ON Then Cylindrical Feeder Forward = ON.

Step 6 :

1. If Cylindrical Feeder Forward = ON And Feeder FWD Limit = ON Then Cylindrical Feeder Reverse = ON.

2.a. If Cylindrical Feeder Forward = ON And Feeder FWD Limit = ON Then Cylindrical Lifter UP = ON.

2.b. If Lifter UP Limit = ON Then Cylindrical Lifter UP = OFF.